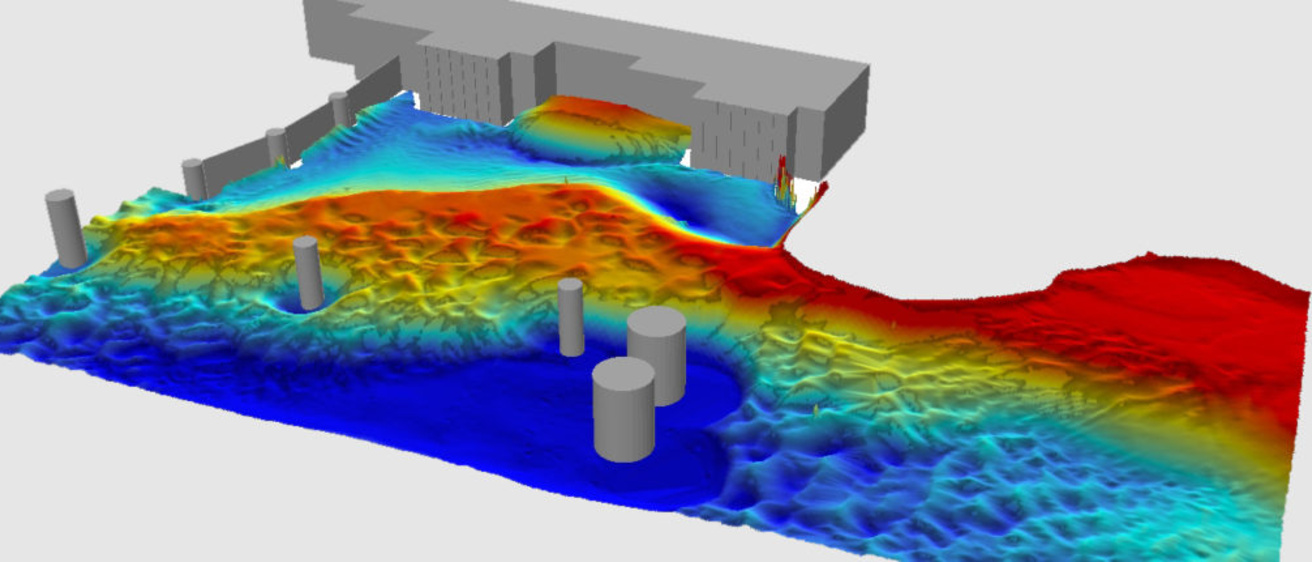

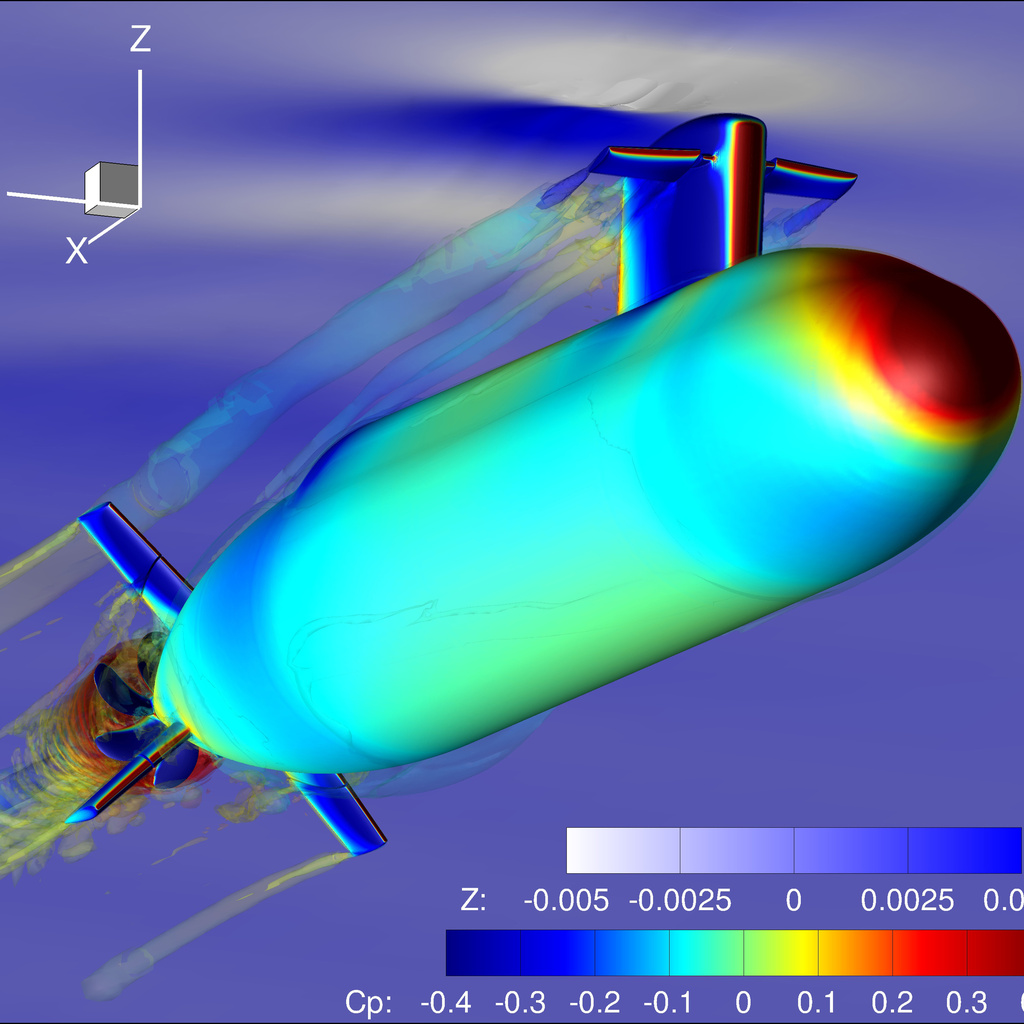

IIHR researchers use simulation-based design — a sort of virtual reality, supported by model-scale experiments — to develop efficient new ways to design and test engineering designs and prototypes. This combination of computer simulation and experimental modeling is on the cutting edge of hydraulic research.

Our fully three-dimensional computer simulations run parallel to physical testing in IIHR’s physical modeling facilities to offer our clients high-quality, validated results. Each form of modeling offers strengths and limitations. Together, they can provide our clients with exciting new insights and solutions.

Fully 3-D Computer Simulations

IIHR has developed 3-D computer simulations based on FLUENT, with several add-on functions written in-house. Researchers can run these computer simulations full-scale, using actual particle sizes and densities.

Temperature Modeling

A particular strength of IIHR’s computer simulation is its ability to model temperature differences. This is an important factor in many situations. In the Cardinal Project, for instance, the team noticed a significant recirculation effect in the power plant’s forebay water intakes. By adding a thermal component to the CFD model, this problem became evident and researchers were able to improve their proposed solutions.

Think Like a Fish

With colleagues at the U.S. Army Corps of Engineers, IIHR has implemented a computer model that simulates the movement of fish near a hydroelectric dam. The insights the model made possible led to new fish passage designs with flared entrances to make flow accelerations more gradual.

Featured CFD Projects